I spend quite a bit of my spare time tinkering with guns, and cleaning them is a large part of that. Obviously, when you clean them, you’re going to take them apart to a greater or lesser extent, depending on what level of “clean” you’re going for.

Back in the day, I used to completely detail strip my guns every time I shot them, but over the course of many years, I found it unnecessary for routine cleaning, and reserve that level of disassembly for deep cleaning, parts replacement or repair work. Most of the time, guns can go quite a few rounds between cleanings without significant damage, but like any machine, they benefit from regular cleaning and maintenance.

With that in mind, let’s move on to one of the good reasons for detailed disassembly, which is inspection of the internal parts, with emphasis on the recoil system. More than anything else, the recoil spring in a semi-auto is vital to proper function, and when it wears out, bad things start happening.

When I worked as a gunsmith, I performed a lot of repairs on firearms that suffered from long-term use and almost no maintenance of their recoil systems. They got cleaned regularly (or whenever) in most cases, but that’s not enough.

A bad recoil or action spring leads to other problems besides affecting reliability, such as peening or impact damage on receivers, frame rails and the like, cracked, broken/chipped parts, accelerated wear and a whole lot of other issues that can eventually destroy even the most expensive and well-made guns.

Amazingly enough, I’ve read through quite a number of owner’s manuals for a whole host of different firearms, and aside from the basic instructions on how to use and clean the weapon (and admonishments on not shooting yourself or others by accident), there’s isn’t a word anywhere about periodic replacement of recoil system parts. Given that these are parts that WILL wear out, I’m surprised that this isn’t addressed more fully in manufacturers’ literature.

Fortunately, sourcing and replacing these parts is super easy, and in my opinion, represents the cheapest, simplest insurance against failure and premature wear for every type of gun you can imagine. Installation is now a simple matter of watching a Youtube video and following the directions.

How do you tell if your recoil system needs work? That’s pretty easy, too. Malfunctions are a pretty good indicator, but not the only one.

Another common way to determine if your recoil spring is giving out is to look at the front edges of your frame rails on semi-auto handguns, and (usually) the back of the receiver in long guns. The impact marks caused by worn recoil system parts will leave blemishes in the surface finish, and can eventually deform the metal around the area, leaving a clean imprint of the bolt/bolt carrier or slide. This is especially evident on older guns that have seen many years of use in the field.

Some guns will exhibit sharper or more pronounced felt recoil due to the increased speed of the parts cycling back and forth.

Strange malfunctions that seem unrelated to the recoil system can also result:

I worked on what appeared to be a very well cared-for West German SIG P226 that continually left a case stuck in the chamber and jammed the next cartridge in line up behind it. Despite scrubbing the chamber, cleaning and inspecting the entire gun, it just would not stop malfunctioning. Finally, I tumbled to replacing the recoil spring with a new one, and the stuck case issue disappeared.

The only thing I can figure is that the recoil spring decreased the amount of time that the slide stayed locked while the bullet was still in the barrel, and allowed it to begin its rearward travel before the case, still under gas pressure, had contracted in the chamber. The extractor claw rode over the case rim and left the case stuck in the chamber, and the next round in the magazine column had nowhere to go.

That’s my story and I’m sticking to it.

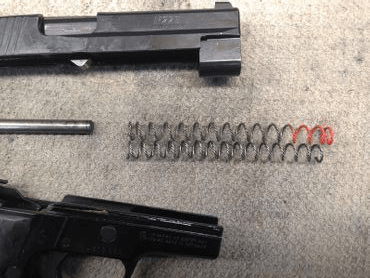

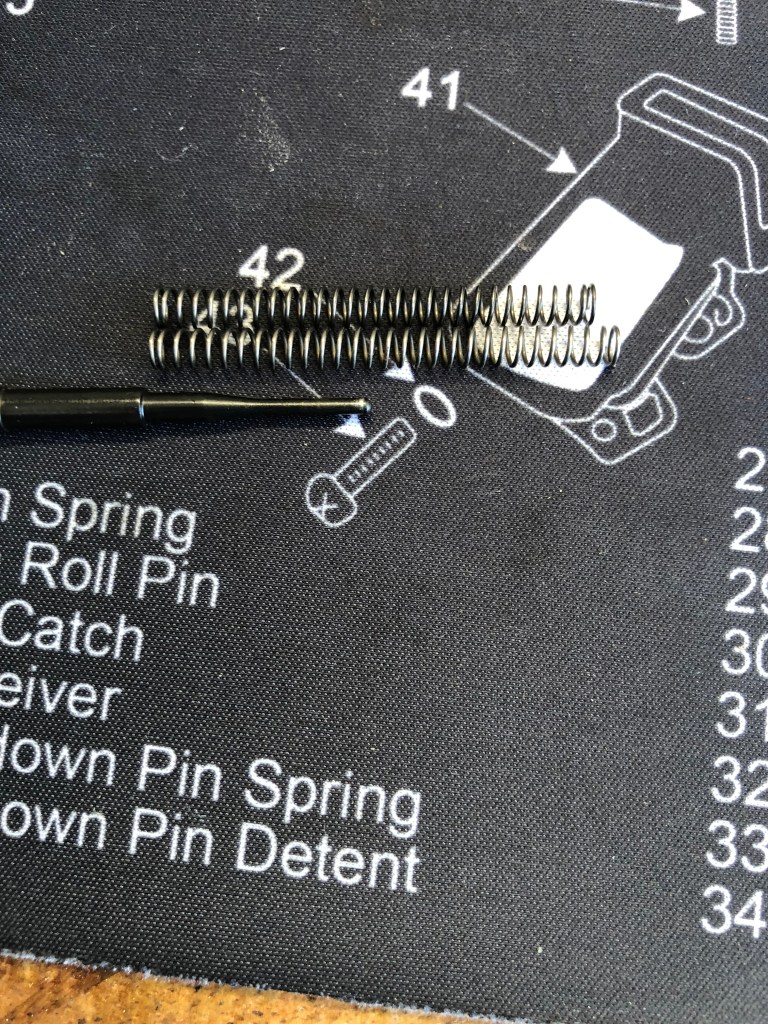

Another way to tell if a spring is giving out is to look for bends or warpage. If your spring is “off-kilter,” it’s probably a good time to replace it, and this goes for magazine springs and other internal springs as well.

I recently replaced the springs in a Browning 1911-380 that had upward of 6,000 rounds on it, and the difference between the old and new springs was pretty significant. Given the high round count, I decided to replace the recoil, firing pin and main springs to ensure reliable function. A further step is to record the date of replacement and keep a round count, if you’re so inclined, but a good rule of thumb is to replace the recoil and other internal springs on a periodic basis depending on how often and how regularly the firearm is used.

I typically swap out my handgun recoil springs around every 1500 to 2000 rounds, and my sub-compact 1911s every 1000 rounds. I prefer Wilson Combat Flat-Wire recoil springs, because they tend to smooth out the slide travel, in my experience, and I like them. They’re advertised as having a longer service life than regular springs, but I’ll probably never put that to the test, because I like my guns and don’t want to beat them to death to prove a point.

One small note: DO NOT stretch out your gun springs or your magazine springs to get a little more power out of them. Stretching them does exactly the opposite. By way of example, if you ever have to cut a piece of hardened wire without a set of cutters, you can select the spot you want to cut and then bend the wire repeatedly back and forth at that spot, weakening it until it breaks. That’s basically what happens to the wire in a spring when you stretch it out.

Besides, springs are really cheap, and there’s a ton of places like Brownell’s and Midway USA where you can get them without much fuss, so replace the old springs rather than attempt to stretch them out. The gun you save may be your own.

While this article has focused mainly on handguns, long guns can also benefit from swapping out recoil system parts on a regular basis, depending on the amount of usage they see. Rifles, shotguns, really anything with spring-powered reciprocating parts can benefit from it, and I definitely recommend keeping spare springs on hand just in case.

They type of ammunition used also has a bearing on spring life, and it’s very important to use springs of the proper weight to compensate for more powerful ammunition, such as +P and +P+ ammo that will beat a handgun action to death if fired excessively without the use of upgraded springs.

So, obviously, there’s a lot of things to consider here, but in practice, its a lot easier than it sounds. Most gun manufacturers and gun parts retailers sell replacement spring kits for very reasonable prices, and aftermarket companies like Wolff offer kits in different weights for almost any modern firearm and ammo combination ever made.

Bottom line, swapping out internal springs in your firearms every so often will extend service life, increase reliability and make shooting a lot more fun without maintenance-related malfunctions getting in the way.